Product Lineup

To meet various needs and requests of our customers, we optimize feedstocks and manufacturing conditions to create a wide assortment of products.

Dry Pulp

In 2015, Hyogo Pulp became the first company in Japan to introduce a full-scale pulp drying machine.

It greatly boosted product quality above that of conventional wet pulp, setting the stage for competition with overseas dry pulp suppliers.

Dry Pulp Features

- High Transport Efficiency

Dry pulp holds less moisture than wet pulp, thus doubling the transport efficiency.

One bale of dry pulp transported equals two bales of wet pulp that were previously shipped.

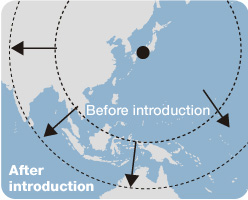

Reduced CO2 emissions during transport helps to mitigate global warming. - Greater Shipping Range

Dry pulp is free from the risks of freezing and molding, and thus can be shipped to distant locations, including overseas destinations. - High Storage Efficiency

Dry pulp does not degrade even when stored for long periods of time. Moreover, storage area can be reduced by 50 percent when switching from wet pulp to dry pulp.

Wire part

Press part

Dryer

Dryer outlet - Cutter

Layboy

Finished Product

Cellofiber

Cellofiber was developed by the company as a suitable construction material that takes advantage of such UKP properties as light weight and excellent processability.

Cellofiber is obtained by fibrillating individual fibers of UKP in a rigorous beating process.* It is a type of wood fiber harmless to people and yet performs similarly to asbestos, which was widely used in the past.

Untreated pulp does not hold cement. Cellofiber, however, can hold cement evenly among its fine fibers. It also possesses excellent anti-alkaline properties and autoclave heat resistance.

For this reason, Cellofiber is widely used in construction as reinforcement for ceramic building materials, such as slate roof tiles, which are made by mixing fibers into cement, and other tiles and bricks.

*Beating process:

A process in which a mixture of water and pulp, which is a mass of fibers, is beaten to produce paper stock.